|

Home | Send models | Technology | Downloads | Price | Gallery | Contact |

3D printing process has changed the way to make jewels. We at Protojewel offer you the most advanced technology with our 3D printing service. We have 4 Solidscape prototyping machines that allow our clients to print their computer generated jewelry modells designed with Rhinoceros and TechGems. To make the process of modells sending easier for our clients, Protojewel offers the free program that is installed inside Rhinoceros. |

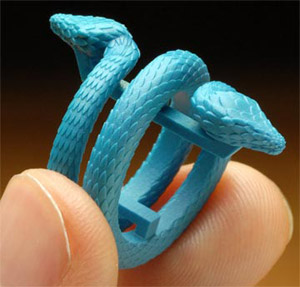

ring modeled with Rhinoceros and printed with con Solidscape |

This program makes the screenshots of the model, labels it, compresses and encrypts it and sends it directly to Protojewel server. Download the program here. |

|

|

Clients who use Protojewel services have their Clients Zone where they can manage their models, accept quotes, consult thier accounts standing, print the invoices, etc. See a demo of Clients Zone here. If you are not familiar with Rhinoceros and TechGems programs, you can learn from tutorials and download evaluation version of the programs. Click here to go to the download page. Printing wax modells allows to create the jewel either directly by casting it in precious metals, or by making the rubber mould and therefore make series of jewels from the molde. Models casted in metal can be treated by all traditional jewelery techniques () to improve the final result and obtain the perfect molde.

|

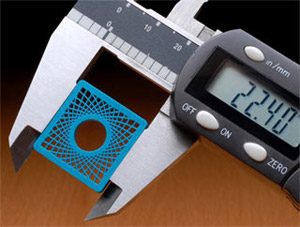

3D printing machine makes the model by superposing thin wax layers, sections of the tridimentional model, until the whole jewel is build. We can print your models in various resolutions depending of the model's structure, starting from 0.0125 mm for very small models with soft curves, up to 0.05 mm for bigger models with straight forms that allow easy polishing. |

|

This allows to optimize the cost of every model and pay the minimum price according to the model's caracteristics. |

|

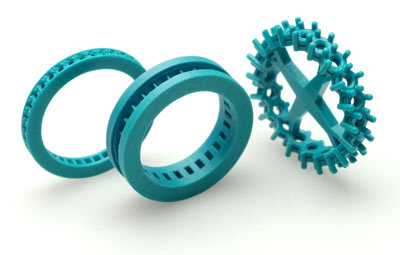

Visit our gallery to see some of the printed models. Thanks to the prototyping system that uses two types of wax, one as support and the other as build material, we can print models with voids or even with hollow interiors. Support wax has lower melting point than the build wax and thanks to that it is easily removed with hot mineral oil and no support structure is needed to build the model. |

|

|

|

© 2006 Techjewel